The telescope is meant to last me for a good few years and so I had to satisfy all the needs and desires I can expect to have for the future. The specification of my “perfect" telescope was based on experiences with my previous scopes, and looking at and through others at Star Parties etc.

Aperture - I have a good 102mm APO refractor which is portable and so for this scope the biggest aperture I could manage (physically and financially) was number one priority.

Optical Arrangement - Obviously a reflector and the trusty Newtonian seemed ideal as I was to buy the mirror "off the shelf". Without my own machine shop more advanced designs were not really practicable. I wanted low expansion glass for the primary mirror and a survey of prices showed that 18" (460mm) was a good compromise. Anything bigger and the prices are astronomical! F4.4 was chosen since portability was not required. I paid extra for 1/10 wave a certificate of conformity with test results - well worth the extra.

Mount - Equatorial and stable. I am a visual observer only. The scope was to be permanently mounted in an observatory, so I had plenty of options although at 50kg the OTA (optical tube assembly) was likely to be too much for a GEM (German Equatorial Mount). At this stage I hadn't settled on a domed observatory, so a high north pier might have been a problem, so that ruled out English equatorial and yoke mounts.

That left me with a fork mount, it was going to have be big & heavy, but done right it should look and perform great.

Drive - I am a supporter of “GOTO" scopes once you have learnt the basics. I found a supplier of 14" (356mm) diameter worm gear sets, and another supplier who provides intelligent drive systems for custom applications.

The tube assembly was made out of three wooden box sections, joined by aluminium tubing in a classic Serrier truss. The wood is best quality 12mm Baltic birch ply and the top and bottom boxes were made octagonal. The centre box is square and heavily reinforced as it has to take two declination stub axles that hold the optical tube in the fork. These stub axles are perhaps the most stressed components so I had them custom made by a professional machinist.

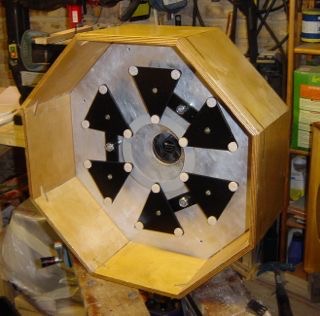

The mirror sits on a 18 point floating support and has a cooling fan installed in the rear of the box. The secondary has a built in dew heater and the 2" focuser was picked up at a swap meet,

The fork is a combination of birch ply and 6mm aluminium plate. For the main supports I used multiple thicknesses of ply (up to 36mm in some areas) . As a box structure it is inherently very strong and stable and after a few years it has been perfectly stable.

The base of the fork has an internal box made from 20mm thick aluminium plate, which carries the 40mm stainless steel RA shaft. The shaft is fixed to the fork and is carried on a pair of heavy duty roller bearings on the polar wedge. This shaft and bearings are at this point carrying more than 150kg of telescope!

The 14"worm gear sets are mounted on both axis and driven by high torque direct drive stepper motors. These are driven by an AWR Intelligent Drive system which is linked to a pc. On the pc I currently use The Sky 6 and Maxim DL to control telescope and ccds, with an ASCOM hub providing an interface to my custom dome control drive servo. The whole set-up can be remotely controlled from another pc in the house (ie in the warm!) via a 1Ghz LAN.

More details can be found in a presentation I gave at the 2005 TSP (see my Articles page)